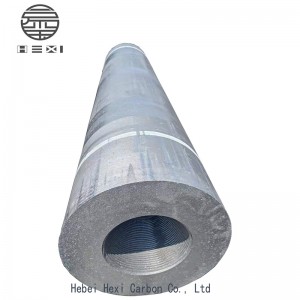

Grafitna elektroda ultra visoke moči

Glavne surovine telesa grafitnih elektrod z izjemno visoko močjo so uvoženi naftni igelni koks. Proizvodni proces vključuje drobljenje, sejanje, doziranje, gnetenje, oblikovanje, pečenje, impregnacijo, drugo pečenje, grafitizacijo in strojno obdelavo. Surovina nastavkov je uvoženi oljni igelni koks, proizvodni proces vključuje trikratno impregnacijo in štirikratno pečenje.

Uporablja se v obločni peči za izdelavo jekla

material grafitne elektrode, ki se uporablja za električno obločno peč za proizvodnjo jekla, se uporablja predvsem za proizvodnjo jekla v električnih pečeh. Proizvodnja jekla v električni peči je uporaba študije grafitne elektrode v delovni tok peči, močan tok na dnu elektrode skozi to plinsko okolje lahko povzroči vpliv praznjenja obloka, uporaba toplote obloka za taljenje. Velikost kapacitivnosti, pri čemer imajo grafitne elektrode elektrode različnih premerov, ki se lahko uporabljajo neprekinjeno, proti povezavi med elektrodama elektrodnega spoja. Približno 70 do 80 % celotne količine grafitne elektrode, ki se uporablja na Kitajskem, je grafit, ki se uporablja kot material za elektrode za proizvodnjo jekla.

Standard ultra-močne grafitne elektrode in nastavka

UHP Grafitna elektroda Dovoljena tokovna obremenitev

Ultrazmogljiva grafitna elektroda, ki jo proizvaja Hexin Carbon, je izdelana iz visokokakovostnega igelnega koksa, njena grafitizacijska toplotna obdelava pa se izvaja v notranji serijski grafitizacijski peči, temperatura grafitizacije pa je kar 2800〜3000 °C, tako da upornost je nižja, kar omogoča večjo gostoto toka, manjši koeficient linearne razteznosti in odlično odpornost na toplotni udar. Je posebna grafitna elektroda z izjemno visoko močjo za elektroobločne peči in peči za rafiniranje z lonci. Grafitna elektroda z izjemno visoko močjo podjetja Hexi Carbon sprejme najnaprednejšo tehnologijo in je proizvedena v strogem skladu z globalnimi standardi, ki v bistvu ustrezajo standardom kakovosti svetovnega razreda. Naše podjetje obljublja brezplačno svetovanje in namestitev, brezplačno sledenje po prodaji in brezpogojno vračilo težav s kakovostjo.

Prevoz elektrod

Med transportom mora biti elektroda prekrita s krpo, ki je odporna na dež.